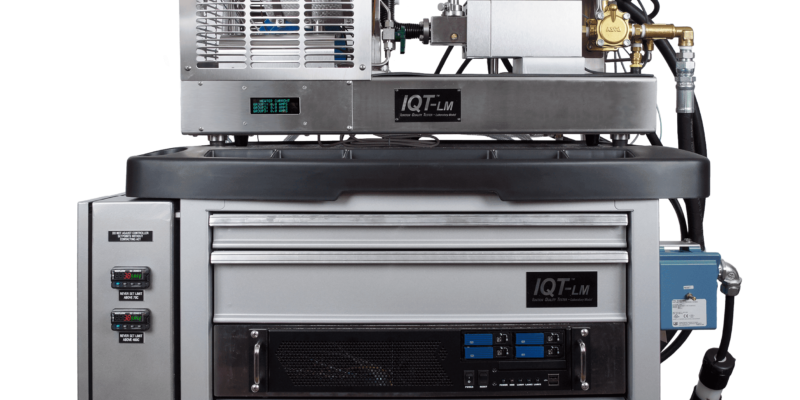

Ignition delay testing is the linchpin in deciphering the quality and prowess of fuels. Enter the IQT Lab Model, affectionately known as IQT-LM, a foundational yet remarkably potent tool for ignition delay testing that has been a torchbearer since its inception in 1998. This comprehensive guide unwraps the myriad features and advantages of the IQT-LM, showcasing its unwavering reliability and precision in fuel testing.

Precision Redefined with High Precision Fuel Injection System (HP-FIS):

The IQT-LM model flaunts the standard High Precision Fuel Injection System (HP-FIS). This sophisticated system guarantees surgical precision in fuel injection for ignition delay testing, establishing the bedrock for consistently reliable results. While the LM model may lack the automation and precision finesse of its TALM counterpart, it remains an indomitable and trustworthy option for fundamental testing needs.

Unveiling Specifications and Standards:

The IQT Lab Model emerges as the go-to apparatus for conducting ignition delay and Derived Cetane Number (DCN) tests on a spectrum of fuel types. It stands tall in compliance with the paramount standards, including ASTM D6890, EN 15195 (IP 498), and ASTM D6751:

- ASTM D6890: Standard Test Method for Determination of Ignition Delay and DCN of Diesel Fuel Oils by Combustion in a Constant Volume Chamber.

- EN 15195 (IP 498): Liquid petroleum products – Determination of ignition delay and DCN of middle distillate fuels by combustion in a constant volume chamber.

- ASTM D6751: Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels.

Sleek Interface for Seamless Operation:

Each IQT system is delivered with a Windows 10 PC running the IQT TALM K2 software, an interface that not only dazzles but enhances visibility for monitoring tests. It’s an ergonomic marvel, ensuring convenient use in a lab setting. The accompanying monitor display guarantees swift access to critical data and test progress.

Fortified Data Security with Backup and Redundancy:

The IQT Lab Model goes the extra mile with its fully integrated data backup system. Picture this: the entire computer system automatically backed up to an internal drive, an added layer of security for your invaluable data. The primary drive, boasting RAID 1 redundancy, ensures uninterrupted operation even in the face of disk drive mishaps, easily replaceable without skipping a beat.

Bounty of Features:

- The TALM K2 software is not just a tool; it’s a visual feast for quick assessment.

- Automated calibration, a must for deploying the Extra-Large (95 mL, stainless steel) Fuel Reservoir Assembly.

- The IQT system aligns seamlessly with fuel specification test methods.

- It unfolds automated test procedures, operates in hushed tones, and is effortlessly navigable.

- Swift test times, a mere 17 minutes, promise a productivity bonanza.

- Elevate productivity further with the K9 self-sealing reservoirs and a cleaning/filling station, enabling preparation of multiple fuel samples for testing well in advance.

- Compatible with either the TALM-K7 electronic pressure regulator system (K1 not a prerequisite) or the mechanical pressure panel.

- The IQT exhibits sensitivity to cetane improver additives and even minor fuel quality nuances.

- Capable of measuring substantial cetane improver levels (3000 ppm+ 2EHN) with zero negative carryover effects.

- A proven maestro in testing highly paraffinic fuels derived from synthesis or hydro-treatment.

- The IQT Lab Model demands a mere sip, a sample size of less than 100 mL.

- It’s a paragon of reliability, a rugged titan with low operating and maintenance costs.

- Maintenance is a breeze, and its safety track record is etched in stone over countless years.

- It’s the undisputed champion in testing B100 and assorted biodiesel fuels from diverse sources.

In Summation:

To sum it up, the IQT Lab Model (IQT-LM) is the epitome of reliability and precision in the realm of ignition delay testing for fuels. With a rich history dating back to its inception in 1998, the IQT-LM continues to be the preferred choice for professionals and researchers globally.

Addressing FAQs with Flair:

What is the IQT Lab Model (IQT-LM)?

The IQT Lab Model, or IQT-LM, is the maestro of ignition delay testing, crafted to assess the quality and performance of diverse fuels. It proudly sports the High Precision Fuel Injection System (HP-FIS) and excels in tests aligned with industry standards.

What are the key standards that the IQT-LM complies with?

The IQT Lab Model is the designated gear for fuel testing in line with critical standards like ASTM D6890, EN 15195 (IP 498), and ASTM D6751. These standards cast a wide net, covering an array of fuel types and characteristics.

How user-friendly is the IQT-LM’s interface?

The IQT-LM flaunts the IQT TALM K2 software, an interface that’s not just user-friendly but a visual delight. It beckons with high-visibility test monitoring, making the assessment of progress and data a walk in the park.

Can the IQT-LM withstand data loss in case of system failure?

Without a doubt! The IQT Lab Model boasts a seamlessly integrated data backup system, autonomously safeguarding the entire computer system to an internal backup drive. Additionally, the primary drive’s RAID 1 redundancy guarantees data security and system resilience in the face of drive hiccups.

What are the additional features of the IQT-LM?

A parade of features adorns the IQT Lab Model, including strikingly visible test monitoring via the TALM K2 software, automated calibration (a must for specific fuel reservoir assemblies), rapid test times (around 17 minutes), and the capacity to measure lofty levels of cetane improver additives sans negative carryover effects.

Is the IQT-LM compatible with various fuel types?

Absolutely! The IQT-LM is tailored for testing a myriad of fuel types, encompassing highly paraffinic fuels derived from synthesis or hydro-treatment. Its versatility positions it as an indispensable tool for analysing an eclectic mix of fuel samples.

Is the IQT-LM easy to maintain?

Maintaining the IQT Lab Model is a breeze, with easy access for upkeep and a track record of safety etched in stone over numerous years. It stands tall as a rugged system with operating and maintenance costs that won’t break the bank.

What is the testing capability of the IQT-LM regarding biodiesel fuels?

The IQT Lab Model boasts a proven testing capability for B100 and assorted biodiesel fuels from diverse sources. It’s a stalwart choice for conducting tests on biodiesel blends, adding another feather to its illustrious cap.

Read tech related blog posts by visiting this website.