In the dynamic field of manufacturing, the ability to produce complex parts quickly and accurately is a significant advantage. Mechplus Tech Co., Ltd. excels in SLS rapid machining manufacturing, leveraging advanced technologies and innovative processes. This article explores the benefits, applications, and technical expertise behind Mechplus Tech’s SLS rapid machining manufacturing capabilities.

What is SLS Rapid Machining Manufacturing?

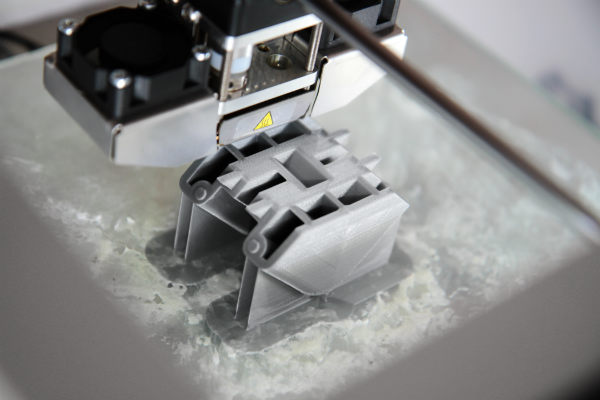

Selective Laser Sintering (SLS) rapid machining manufacturing is an advanced additive manufacturing process that uses a high-power laser to fuse small particles of plastic, metal, or ceramic into detailed and accurate parts. This layer-by-layer approach allows for the creation of complex geometries that are difficult or impossible to achieve with traditional machining methods. Mechplus Tech utilizes SLS technology to deliver high-quality parts with exceptional precision and speed.

Advantages of SLS Rapid Machining Manufacturing

- Complex Geometries: The ability to create intricate shapes and structures.

- High Precision: Exceptional accuracy in producing detailed parts.

- Reduced Lead Times: Faster production cycles compared to traditional methods.

- Material Versatility: Works with a variety of materials, including plastics, metals, and ceramics.

- Cost Efficiency: Minimizes material waste and reduces overall production costs.

Mechplus Tech Co., Ltd.: Leaders in SLS Rapid Machining Manufacturing

Mechplus Tech Co., Ltd. has established itself as a leader in SLS rapid machining manufacturing, offering comprehensive solutions that cater to diverse industrial needs. Their expertise in quick response machining tools and rapid response manufacturing sets them apart from the competition.

Quick Response Machining Tool

The quick response machining tool is integral to Mechplus Tech’s SLS rapid machining manufacturing capabilities. This tool is designed to optimize the machining process by significantly reducing setup and cycle times. The quick response machining tool enhances Mechplus Tech’s ability to deliver high-quality parts within tight deadlines, making them a preferred partner for industries requiring fast and reliable manufacturing solutions.

Rapid Response Manufacturing

Rapid response manufacturing is critical in today’s fast-paced market. Mechplus Tech Co., Ltd.’s SLS rapid machining manufacturing ensures that they can meet urgent production requirements without compromising on quality. Their ability to quickly adapt to changes in design or production volume makes them an ideal partner for dynamic industries.

Quick Turn Machining

Quick turn machining is another area where Mechplus Tech Co., Ltd. excels. By integrating their SLS rapid machining capabilities, they provide rapid turnaround times, enabling clients to meet tight deadlines. This capability is essential for maintaining a competitive edge and ensuring timely delivery of products.

Applications of SLS Rapid Machining Manufacturing

The versatility of SLS rapid machining manufacturing makes it suitable for various applications across multiple industries, including aerospace, automotive, medical devices, and more. Mechplus Tech has successfully delivered precision parts for complex assemblies, prototype development, and mass production, showcasing their expertise across various sectors.

Technical Expertise

Mechplus Tech employs a team of skilled engineers and technicians who are proficient in operating advanced SLS machinery. Their technical expertise ensures that each project is executed with precision and efficiency, meeting the highest standards of quality and performance.

Quality Assurance

Quality assurance is a fundamental aspect of Mechplus Tech Co., Ltd.’s operations. Rigorous quality control measures are implemented at every stage of the manufacturing process to ensure that each part meets the required specifications. Advanced inspection tools and techniques are used to verify the accuracy and consistency of the final product.

FAQs

1. How does SLS rapid machining manufacturing benefit from quick response machining tools?

Quick response machining tools significantly reduce setup and cycle times, enabling rapid production cycles. This capability allows Mechplus Tech Co., Ltd. to meet urgent production requirements efficiently and reliably.

2. What materials can be used in SLS rapid machining manufacturing?

SLS rapid machining manufacturing at Mechplus Tech Co., Ltd. can work with a variety of materials, including plastics, metals, and ceramics. This versatility allows for the production of detailed and accurate parts across different industries and applications.

3. Can Mechplus Tech Co., Ltd. handle both prototype and mass production projects?

Yes, Mechplus Tech Co., Ltd. is equipped to handle projects of all sizes, from single prototypes to large-scale mass production. Their flexible manufacturing capabilities and quick response machining tools enable them to meet diverse client demands efficiently.

Conclusion

Mechplus Tech Co., Ltd. is revolutionizing the manufacturing landscape with their SLS rapid machining manufacturing capabilities. By integrating quick response machining tools and rapid response manufacturing, they provide comprehensive solutions that cater to the dynamic needs of various industries. Their commitment to quality, innovation, and customer satisfaction positions them as a trusted partner in the competitive world of manufacturing.