The meat processing industry is a complex and highly regulated sector that requires meticulous attention to detail, from managing raw materials to ensuring product quality and regulatory compliance. In this highly competitive market, companies are constantly seeking ways to optimize operations, reduce costs, and maximize profits. One of the most effective tools to achieve these goals is advanced Enterprise Resource Planning (ERP) software. This blog will explore how implementing ERP software can revolutionize meat processing operations, streamline processes, and ultimately boost profitability.

Understanding ERP Software

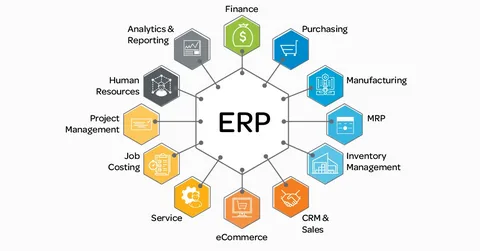

ERP software is a comprehensive business management solution that integrates various functions across an organization into a unified system. It provides real-time visibility into core business processes, facilitating better decision-making and improving efficiency. For the meat processing industry, ERP software can encompass a wide range of functionalities, including inventory management, production planning, quality control, traceability, compliance, and financial management.

Key Benefits of ERP Software in Meat Processing

- Streamlined Operations

ERP software helps meat processing companies streamline their operations by automating and integrating various business processes. This includes everything from procurement and production to sales and distribution. By eliminating manual processes and reducing redundancies, ERP systems enable companies to operate more efficiently, saving time and reducing operational costs. - Improved Inventory Management

Effective inventory management is crucial in the meat processing industry, where the shelf life of products is limited, and wastage can significantly impact profitability. ERP software provides real-time visibility into inventory levels, helping companies track raw materials, work-in-progress, and finished goods. This enables better demand forecasting, reduces stockouts and overstock situations, and minimizes waste. - Enhanced Traceability and Compliance

Traceability is a critical aspect of the meat processing industry, especially with increasing consumer demands for transparency and stringent regulatory requirements. ERP software allows companies to track every step of the production process, from farm to fork. This ensures that all products can be traced back to their source, facilitating compliance with food safety regulations and enhancing consumer trust. - Optimized Production Planning

Production planning in meat processing involves coordinating various activities, such as slaughtering, cutting, packaging, and distribution. ERP software helps optimize production schedules by considering factors like demand forecasts, inventory levels, and production capacities. This ensures that production processes are aligned with market demand, reducing idle time and maximizing resource utilization. - Improved Quality Control

Maintaining high-quality standards is essential in the meat processing industry to ensure product safety and customer satisfaction. ERP software integrates quality control processes into the production workflow, allowing companies to monitor and manage quality at every stage. This includes conducting inspections, recording test results, and addressing non-conformities promptly. By maintaining consistent quality, companies can reduce recalls, improve brand reputation, and increase customer loyalty. - Efficient Financial Management

ERP software provides robust financial management capabilities, enabling meat processing companies to manage their finances more effectively. This includes budgeting, cost tracking, financial reporting, and analysis. By integrating financial data with other business functions, ERP systems provide a holistic view of the company’s financial health, helping management make informed decisions to maximize profitability.

Implementing ERP Software in Meat Processing

Implementing ERP software in a meat processing company requires careful planning and execution. Here are the key steps involved in the process:

- Needs Assessment

The first step in implementing ERP software is to conduct a thorough needs assessment. This involves understanding the specific requirements and pain points of the company. Key stakeholders from various departments should be involved in this process to ensure that all critical aspects of the business are considered. - Vendor Selection

Choosing the right ERP vendor is crucial to the success of the implementation. Companies should evaluate different ERP solutions based on factors like functionality, scalability, ease of use, and support services. It is also essential to consider the vendor’s experience in the meat processing industry and their ability to provide industry-specific solutions. - Customization and Integration

Once the ERP software is selected, it may need to be customized to meet the specific needs of the meat processing company. This involves configuring the system to align with existing business processes and integrating it with other systems and equipment. Proper customization and integration ensure that the ERP software can effectively support the company’s operations. - Data Migration

Data migration is a critical step in the ERP implementation process. It involves transferring data from existing systems to the new ERP system. This includes data related to inventory, production, quality control, finance, and more. Ensuring data accuracy and completeness is vital to avoid disruptions during the transition. - Training and Change Management

Training employees on how to use the new ERP system is essential for a successful implementation. Comprehensive training programs should be conducted to ensure that all users are comfortable with the new system and understand how to leverage its features effectively. Additionally, change management strategies should be implemented to address any resistance to change and ensure a smooth transition. - Testing and Go-Live

Before going live with the ERP system, thorough testing should be conducted to identify and resolve any issues. This includes testing various functionalities, workflows, and integrations. Once testing is complete and any necessary adjustments are made, the ERP system can be deployed. It is advisable to have a phased go-live approach to minimize disruptions and address any challenges that may arise.

Successful ERP Implementation in Meat Processing

To illustrate the impact of ERP software on meat processing, let’s consider a case study of a mid-sized meat processing company that successfully implemented an ERP system.

Company Overview

The company MeatPro, specializes in processing and distributing a wide range of meat products, including beef, pork, and poultry. Before implementing ERP software, MeatPro faced several challenges, including inefficient inventory management, lack of traceability, and manual production planning processes.

Challenges Faced

- Inventory Management: MeatPro struggled with managing inventory levels, leading to frequent stockouts and overstock situations. This resulted in increased costs due to wastage and lost sales opportunities.

- Traceability: Ensuring traceability of products was a significant challenge, making it difficult to comply with regulatory requirements and respond to product recalls.

- Production Planning: Manual production planning processes were time-consuming and prone to errors, leading to inefficiencies and delays in meeting customer demands.

ERP Implementation Process

- Needs Assessment: MeatPro conducted a thorough needs assessment to identify the specific requirements and pain points in their operations. This involved input from key stakeholders across various departments.

- Vendor Selection: After evaluating several ERP vendors, MeatPro selected a solution that offered robust functionalities for inventory management, traceability, and production planning.

- Customization and Integration: The ERP system was customized to align with MeatPro’s existing business processes and integrated with their existing equipment and systems.

- Data Migration: Data from MeatPro’s legacy systems were carefully migrated to the new ERP system, ensuring accuracy and completeness.

- Training and Change Management: Comprehensive training programs were conducted for all employees, and change management strategies were implemented to address any resistance to the new system.

- Testing and Go-Live: Thorough testing was conducted to identify and resolve any issues before going live. MeatPro adopted a phased go-live approach to minimize disruptions.

Results Achieved

- Improved Inventory Management: MeatPro achieved real-time visibility into inventory levels, reducing stockouts and overstock situations. This led to a significant reduction in wastage and improved cost efficiency.

- Enhanced Traceability: The ERP system provided end-to-end traceability of products, enabling MeatPro to comply with regulatory requirements and respond promptly to product recalls. This enhanced consumer trust and improved brand reputation.

- Optimized Production Planning: Automated production planning processes enabled MeatPro to align production schedules with market demand, reducing idle time and maximizing resource utilization. This resulted in improved efficiency and on-time deliveries.

- Better Decision-Making: The ERP system provided MeatPro’s management with real-time insights into key business metrics, facilitating better decision-making and strategic planning. This contributed to improved profitability and business growth.

Future Trends in ERP for Meat Processing

As technology continues to evolve, ERP software for the meat processing industry is expected to incorporate several advanced features and capabilities. Here are some future trends to watch out for:

- Artificial Intelligence and Machine Learning

AI and machine learning technologies are poised to revolutionize ERP systems by enabling predictive analytics, automated decision-making, and process optimization. In the meat processing industry, AI can be used for demand forecasting, quality control, and predictive maintenance, further enhancing efficiency and profitability. - Internet of Things (IoT) Integration

IoT devices can provide real-time data from various stages of the production process, enabling better monitoring and control. Integrating IoT with ERP systems can enhance traceability, improve inventory management, and optimize production processes. - Cloud-Based ERP Solutions

Cloud-based ERP solutions offer several advantages, including scalability, flexibility, and cost-effectiveness. Meat processing companies can benefit from cloud-based ERP systems by accessing real-time data from anywhere, facilitating collaboration, and reducing IT infrastructure costs. - Blockchain for Enhanced Traceability

Blockchain technology can provide an immutable and transparent record of the entire supply chain, enhancing traceability and food safety. Integrating blockchain with ERP systems can help meat processing companies ensure the authenticity and integrity of their products.

Conclusion

Implementing advanced ERP software can significantly transform meat processing operations, enabling companies to streamline processes, improve efficiency, and maximize profits. From inventory management and production planning to quality control and compliance, ERP systems provide comprehensive solutions to address the unique challenges of the meat processing industry. As technology continues to advance, the future of ERP in meat processing looks promising, with AI, IoT, cloud computing, and blockchain set to further enhance operational efficiency and profitability. For meat processing companies looking to stay competitive and achieve sustainable growth, investing in advanced ERP software is a strategic move that can deliver substantial benefits.