Introduction

Welcome to the era of unprecedented productivity – Automated manufacturing technology has revolutionized production processes, unlocking new levels of efficiency and performance. In this article, we explore how leveraging automated manufacturing technology can optimize productivity and drive success in modern industries.

Outline

- Understanding Automated Manufacturing Technology

- Technological Advancements

- Applications Across Industries

- Benefits and Advantages

- Challenges and Considerations

- Conclusion

- FAQs

Background

Understanding Automated Manufacturing Technology: Automated manufacturing technology encompasses a wide range of cutting-edge tools and systems designed to automate and optimize production processes. From robotics to artificial intelligence, these technologies work in harmony to streamline operations and maximize output.

Technological Advancements

Discover the latest advancements in automated manufacturing technology:

- Robotics: Advanced robotic systems perform tasks with precision and speed, ranging from assembly and welding to material handling and packaging, enhancing efficiency and reducing labor requirements.

- Artificial Intelligence (AI): AI algorithms analyze vast amounts of data to optimize production schedules, predict maintenance needs, and improve quality control, leading to higher productivity and reduced downtime.

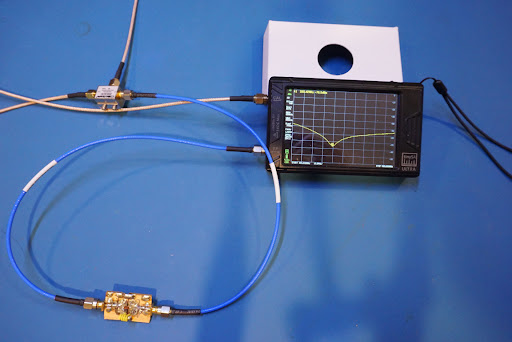

- Internet of Things (IoT): IoT sensors and devices collect real-time data from manufacturing equipment, enabling remote monitoring, predictive maintenance, and adaptive process control, improving overall equipment effectiveness (OEE) and uptime.

- Advanced Analytics: Data analytics tools process and analyze manufacturing data to identify trends, patterns, and opportunities for optimization, enabling data-driven decision-making and continuous improvement initiatives.

Applications Across Industries

Explore the diverse applications of automated manufacturing technology:

- Automotive: Automated manufacturing technology revolutionizes automotive production with robotic assembly lines, AI-driven quality control, and additive manufacturing of custom components, increasing efficiency and innovation.

- Electronics: In the electronics industry, automated manufacturing technology ensures precise assembly of circuit boards, surface mount technology (SMT) soldering, and automated testing, ensuring high-quality and reliable products.

- Consumer Goods: Automated manufacturing technology streamlines the production of consumer goods such as appliances, furniture, and packaging, ensuring consistency and quality while reducing production costs.

- Pharmaceuticals: In the pharmaceutical industry, automated manufacturing technology enables the production of drugs and medical devices with high precision and compliance with regulatory standards, improving patient outcomes and safety.

Benefits and Advantages

Discover the benefits of leveraging automated manufacturing technology:

- Increased Productivity: Automated manufacturing technology optimizes production processes, reduces cycle times, and improves resource utilization, leading to higher productivity and throughput.

- Improved Quality: By minimizing errors, defects, and variability in production processes, automated manufacturing technology ensures superior product quality and reliability, reducing rework and warranty costs.

- Cost Savings: Automated manufacturing technology reduces labor costs, material waste, and downtime, resulting in overall cost savings and improved profitability.

- Flexibility and Scalability: With the ability to quickly adapt to changing production needs and market demands, automated manufacturing technology ensures agility and responsiveness, enabling manufacturers to remain competitive in dynamic markets.

Challenges and Considerations

Navigate the challenges associated with leveraging automated manufacturing technology:

- Initial Investment: Implementing automated manufacturing technology requires significant upfront investment in equipment, infrastructure, and training, necessitating careful financial planning and ROI analysis.

- Integration Complexity: Integrating automated systems with existing manufacturing processes may be complex and require specialized expertise, leading to potential disruptions and compatibility issues.

- Workforce Transition: Automation may require reskilling or upskilling of the workforce to operate and maintain automated systems, requiring comprehensive training and change management strategies.

- Cybersecurity Risks: Connected automated systems may be vulnerable to cybersecurity threats such as data breaches and malware attacks, necessitating robust cybersecurity measures to protect sensitive data and intellectual property.

Conclusion

In conclusion, leveraging automated manufacturing technology is essential for maximizing productivity and driving success in modern industries. By embracing technological advancements and addressing challenges, manufacturers can unlock new opportunities and remain competitive in the ever-evolving global marketplace.

FAQs

Q: What is automated manufacturing technology?

A: Automated manufacturing technology encompasses a wide range of cutting-edge tools and systems designed to automate and optimize production processes, including robotics, artificial intelligence, IoT, and advanced analytics.

Q: What are the benefits of leveraging automated manufacturing technology?

A: The benefits of leveraging automated manufacturing technology include increased productivity, improved quality, cost savings, flexibility, and scalability, enabling manufacturers to optimize operations and remain competitive in dynamic markets.

Q: What challenges are associated with leveraging automated manufacturing technology?

A: Challenges associated with leveraging automated manufacturing technology include initial investment requirements, integration complexity, workforce transition, and cybersecurity risks, necessitating careful planning, implementation, and management strategies.