A grinding wheel is essential to getting the job done right. It is durable and precise, but you must regularly true it up to perform at its best. There are different dressing techniques that you can use to keep your diamond grinding wheels sharp and efficient. Implementing effective diamond grinding wheel alignment methods through dressing techniques offers several benefits

Trueing is the process used to customize the shape of a grinding wheel when it wears from its initial shape. One of the best ways to true your grinding wheel, recommended by experts, is the dressing technique. Read more to understand dressing techniques and how to keep your diamond grinding wheels in the best shape..

Benefits of truing up diamond grinding wheels

- Truing up your diamond grinding wheel is essential for maintaining the quality of your grinding results.

- It helps to ensure a precise and consistent finish on your workpiece and helps to avoid any potential damage to the wheel due to uneven grinding surfaces.

- Truing also increases the life of your diamond grinding wheel as it removes any built-up debris which can cause premature wear or clog.

- Reduces the risk of wheel breakage due to excessive heat buildup and improves the efficiency of your grinding process.

- Helps reduce vibration and noise while increasing operator safety.

All these benefits make it essential to use the proper dressing technique to keep your diamond grinding wheel in the best shape. Implementing effective diamond grinding wheel alignment methods through dressing techniques offers several benefits

Different dressing techniques

There are several different techniques that you can use to dress a grinding wheel. They include the following:

Stick Dressing

Stick dressing is the most common method of truing used to sharpen machines like grinders in production machining. The process involves using a flat stick made from a hard material like carbide or diamond. You must press the stick against the wheel, moving it back and forth in a circular motion until it is true.

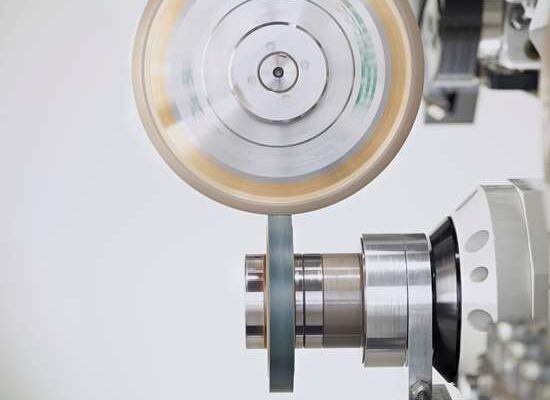

Wheel Dressing

Wheel dressing involves using another diamond wheel to dress the one you want to true. The wheel is slowly passed over the surface of the diamond grinding wheel, removing any irregularities. This method is usually used on small, delicate diamond wheels, as it is more accurate than stick dressing.

Blade Dressing

You can use blade dressing when truing up large diamond wheels. The process involves using a steel blade to cut into the wheel, removing material until the wheel is true. This method can be very effective, but it also creates a lot of dust and debris, so you should do it in a well-ventilated area. Balancing addresses dynamic imbalances in the grinding wheel, reducing vibration and enhancing stability during operation. Various methods, such as static and dynamic balancing, are employed to achieve optimal balance, mitigating the risk of machine damage and enhancing surface finish.

Diamond Roll Dressing

You can use diamond roll dressing to true up diamond wheels with complex shapes or designs. It involves using a diamond-studded roller that presses into the wheel, removing any high spots or irregularities. This method is more expensive than other methods but produces a highly accurate result.

Like all other machinery, grinding wheels wear out after using them for a long time. Therefore, it is important to maintain it regularly to ensure the best performance. Using the right technique for dressing your diamond grinding wheel will ensure it remains in optimum condition for a long time. At PDQ, we offer the best dressing machinery and techniques to true your diamond grinding wheel. Adjusting dressing parameters, including feed rate, depth of cut, and dressing tool speed, optimizes wheel performance and extends its lifespan. Fine-tuning these parameters enhances dressing efficiency while minimizing wheel wear and maintaining dimensional accuracy.

Conclusion

Diamond grinding wheel alignment through advanced dressing techniques is indispensable for achieving precision machining goals. By adopting systematic alignment methods and optimizing dressing processes, industries can enhance productivity, minimize downtime, and deliver superior-quality products, reinforcing their competitive edge in the market. Regular monitoring of wheel condition and performance facilitates proactive maintenance, preventing issues before they escalate. Monitoring techniques such as acoustic emission analysis and force measurement provide insights into wheel integrity, guiding timely dressing interventions and ensuring uninterrupted machining operations.