The many forms of self-sheeting teams might occasionally confuse us concerning their widespread application. Improper usage of these fasteners will eventually cause damage, failure, costly repairs, and safety hazards. To avoid such situations, people should be aware of fundamental knowledge and frequent mistakes to avoid while using self-drilling screws. Understanding the procedure of employing various types of fasteners increases the likelihood of the task being productive and successful.

In this blog post, we will look at several typical mistakes individuals make while utilizing metal sheeting screws.

- Choosing the incorrect material and grade

According to the leading self-drilling screw installation professionals, the first thing to consider when purchasing self drilling metal screws is the substance and grade. There are several materials available, each with its distinct properties that may make it acceptable or unsuitable for a specific application, yet this is insufficient.

However, we must go a step further because each substance is composed of distinct compounds. These various compositions are known as material grades. Each grade has unique properties that make it better suited for some surroundings than others.

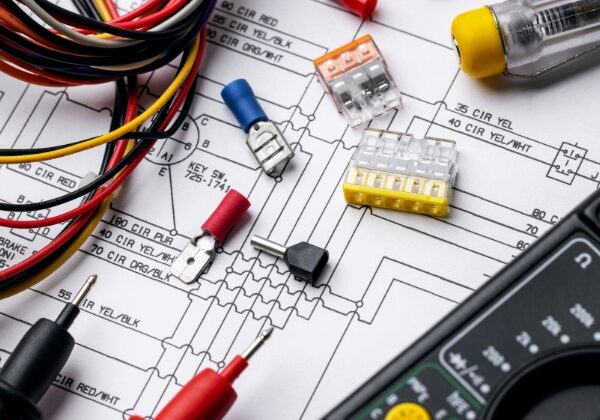

- Using the wrong tools

Using the improper type or brand of metal sheeting screws might have a negative influence on the installation of all fasteners. Leading self-drilling screw installation and application technicians reveal that fasteners have specific drives on their heads, allowing you to select the ideal drive tool for the job. Using the improper tool frequently results in untightened parts or loose assembly.

Furthermore, employing impact tools on screws can degrade their structure, make them difficult to tighten, and cause unequal weight distribution. This can lead screws to become damaged and fail.

- Not using proper locking fasteners

Locking fasteners are a fantastic addition to screw assortment assembly, but there are specific cases where they must be used. According to leading self-drilling screw applications and installation experts, if you’re putting together something that will be subjected to a lot of shaking or vibrations, you should use some type of locking fastener to keep everything secure.

- Mixing threading between Imperial and Metric

Not all fasteners are made equal. Another typical mistake is attempting to fasten the wrong types of fasteners together. Top self-drilling screw installation and application contractors reveal that every form of fastener should be easy to thread by hand.

There are several equipment available to verify the threading and size of fasteners readily. Check the required size before attempting to force the connection.

- Wrong-Sized Drivers

A driver is intended to fully fit the fastener’s driver recess. Always use the correct driver, as a loose driver significantly increases the danger of stripping and came out. Make sure you’re using the correct drive for sockets and wrenches.

Top self-drilling screw installation experts reveal that many people try to utilize an imperial hex Wafer Head Screws or a metric socket since they are a near match.

Conclusion

Working with metal sheeting screws necessitates meticulous attention to detail, adherence to best practices, and collaboration with reliable professionals. You may maintain the endurance and safety of your construction project by avoiding typical mistakes such as inadequate planning, improper handling, faulty installation, failing to consider stability, inaccurate load estimates, and a lack of maintenance.