One of the most important aspects of the copper manufacturing process is the bulk copper cathode process, which is the last step in turning raw materials into premium copper cathodes. This procedure is essential to the metallurgical business and is crucial to satisfying the demand for copper, a crucial metal with a wide range of uses in many industries.

Pure copper cathodes are becoming more and more necessary for industrial operations. Due to its exceptional electrical conductivity and resistance to corrosion, copper is used extensively in a variety of industries, such as manufacturing, electronics, and construction. Businesses rely on pure copper cathode bulk wholesalers to supply this need. This essay will examine the importance of these distributors to the market, how they guarantee the quality of the products they sell, and how they affect different industries.

Knowing the Process of Bulk Copper Cathode

Extracting and Processing Ore

Ores rich in copper are extracted from mines to start the journey. Crushing and grinding are two of the many processing procedures these ores go through in order to extract the rich copper minerals.

Melting

The concentrated copper ore is heated to a high temperature in furnaces during the smelting process, which comes next. Blister copper, or molten copper, is left behind after contaminants are eliminated by this procedure.

Copper Blister Refined

Then, in order to remove contaminants like sulfur and iron, the blister copper is put through refining procedures. In order to be ready for the final cathode manufacturing purchase from the bulk copper cathode supplier, a high degree of purity must be attained.

The Core Process of Cathode Production: Electrorefining

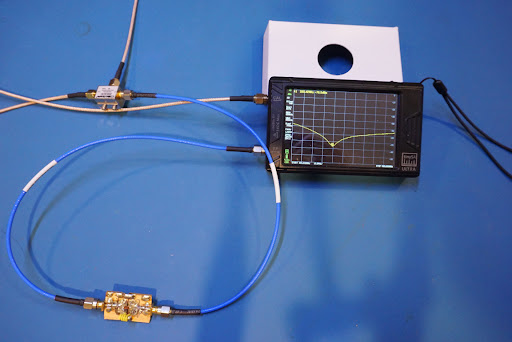

Cells for Electrolysis

The refined blister copper is then put into electrolysis cells for electrorefining, an essential step in the bulk copper cathode process. An anode and a cathode submerged in an electrolyte solution make up these cells.

Depositions of Copper

Copper ions go from the anode to the cathode of the cells when an electric current flows through them. A layer of high-purity copper is progressively formed on the cathode via the deposition of copper.

Observation and Control of Quality

Throughout the electrorefining process, quality control and continuous monitoring are used to make sure the copper cathodes satisfy industry requirements. Close control is applied to parameters like as electrolyte composition and current density.

The Value of Producing Copper Cathodes in Bulk

Superior Purity for a Wide Range of Uses

Because of their high levels of purity, bulk copper cathodes made using this technique may be used in a wide range of industries, such as electronics, construction, and electrical wiring.

Fulfilling Demand Worldwide

The bulk copper cathode process is essential to supplying the steadily rising worldwide copper demand. For their operations, industries all over the world depend on this procedure to guarantee a consistent and superior supply of copper.

- Producing high-purity copper cathodes appropriate for a range of industrial uses is the main goal.

- The use of energy-efficient technology, environmental behaviors, and the investigation of recycling procedures are among the initiatives.

- Market turbulence, the necessity for constant innovation, and the impact on the environment are among the difficulties.

- In order to ensure high-purity cathodes, electrorefining entails depositing copper onto a cathode using electrolysis.

Difficulties in Producing Bulk Copper Cathode Process

Impact on the Environment

Environmental effects may result from the mining, processing, and energy-intensive smelting and refining of copper ores. The ecological footprint is being reduced and sustainable methods are being implemented.

Variations in the Market

The economic feasibility of producing bulk copper cathode is impacted by market swings in the copper sector. Producers have to manage the dynamics of the market and take calculated risks by taking smart action.

Novelties and Progress

Ecological Methods

To lessen the overall effect of producing bulk copper cathode, the industry is investigating sustainable techniques in response to environmental concerns. Examples of these activities include energy-efficient refining technology and recycling procedures.

Integration of Technology

Technological developments, such as automation and digitalization, are being incorporated into the bulk copper cathode process to increase productivity, lower costs, and improve overall results.

Conclusion

The bulk copper cathode process is the last and most important step in the chain of copper manufacture. High-purity copper cathodes are made by smelting, refining, and electrorefining, which satisfies the various demands of industries all over the world. The manufacture of bulk copper cathodes is being shaped by innovations and a dedication to sustainability, even in the face of ongoing problems.