In the dynamic world of hydraulic systems, where efficiency and dependability are non-negotiable, the technology behind hydraulic hoses is continually evolving. One of the most transformative advancements in this field is the skiving process. Skiving hydraulic hoses is not just a technical refinement; it’s a revolution that offers substantial improvements in both performance and durability. For industries relying on hydraulic systems, understanding how skiving works and its benefits can make a significant difference in operational effectiveness and maintenance costs.

What is Skiving?

Skiving Defined

Skiving is a precision process used to prepare hydraulic hoses for the crimping process. It involves carefully removing a section of the outer rubber cover to expose the reinforcement layer, typically composed of steel wire or textile fibers. This technique allows for a stronger, more secure connection between the hose and its fittings, essential for maintaining hydraulic integrity under high pressure.

The Skiving Process

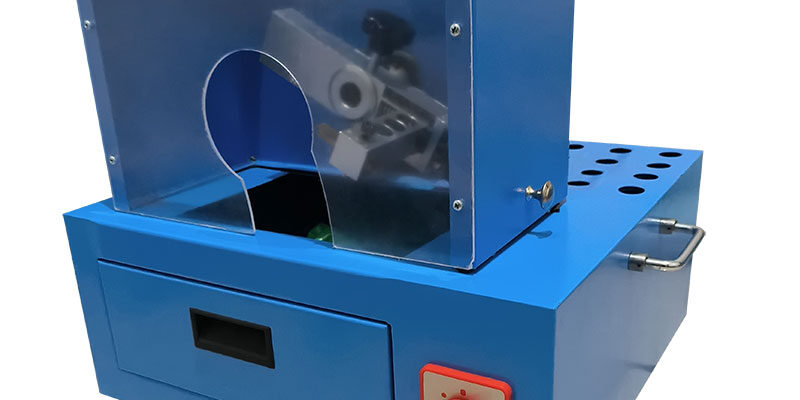

The process begins with placing the hydraulic hose into a skiving machine. This machine uses a rotary cutting tool to strip away the outer cover of the hose to a specified depth. The goal is to expose just enough of the reinforcement layer so that the crimping process can create a robust, leak-proof bond without compromising the hose’s structural integrity.

Advantages of Skiving Hydraulic Hoses

Enhanced Bond Strength

One of the most significant benefits of skiving is the improvement in bond strength. By removing the outer cover, skiving allows for a direct connection between the fitting and the reinforcement layer of the hose. This results in a more secure, leak-proof seal, essential for high-pressure hydraulic applications.

Improved Pressure Handling

Skived hydraulic hoses are better suited to handle high-pressure environments. The exposed reinforcement layer provides a more reliable fit, reducing the risk of hose failure due to pressure fluctuations. This enhanced capability is crucial for industries where high-pressure operations are common, such as in heavy machinery and industrial equipment.

Increased Durability

The durability of hydraulic hoses is significantly enhanced through skiving. The improved bond between the hose and its fittings reduces the likelihood of issues such as slipping or bursting. This leads to a longer service life for the hose and fewer maintenance interventions, making it a cost-effective solution for various industrial applications.

Better Flexibility

Skived hoses offer increased flexibility, making them easier to bend and route without affecting their performance. This flexibility is particularly advantageous in applications requiring complex hose routing or tight spaces. The ability to navigate these challenges effectively improves the overall efficiency of hydraulic systems.

Reduced Risk of Hose Slippage

By exposing the reinforcement layer, skiving minimizes the risk of hose slippage. The fitting can grip the hose more securely, which helps prevent issues associated with hose movement and instability. This secure connection enhances the reliability of hydraulic systems, reducing the likelihood of operational disruptions.

Applications Across Industries

Construction

In the construction industry, hydraulic hoses are integral to the operation of heavy equipment such as excavators and bulldozers. The durability and pressure handling capabilities of skived hoses make them ideal for these demanding applications, where reliability and performance are critical.

Agriculture

Agricultural machinery, including tractors and harvesters, relies on hydraulic systems to perform a range of tasks. Skived hoses offer improved flexibility and bond strength, which contribute to more efficient operation and reduced maintenance needs in agricultural equipment.

Manufacturing

In manufacturing, hydraulic hoses are used in a variety of machinery and processes. The enhanced performance and durability of skived hoses lead to more reliable operation and less downtime, benefiting manufacturing operations that depend on hydraulic systems.

Mining

Mining equipment often operates under extreme conditions, including high pressure and harsh environments. Skived hydraulic hoses can withstand these challenging conditions, providing reliable performance and reducing maintenance requirements for mining machinery.

Future Developments in Skiving Technology

Advancements in Machinery

The future of skiving technology includes innovations in machinery that offer greater precision and efficiency. New developments in skiving equipment feature advanced control systems, allowing for more precise adjustments and customization of the skiving process. These advancements promise to enhance the overall effectiveness of skiving technology.

Enhanced Materials

Future skiving technology may also involve the use of advanced materials for hydraulic hoses. These materials could offer improved performance characteristics, such as greater resistance to wear and tear or better pressure handling capabilities. The integration of these materials with skiving technology could further revolutionize hydraulic hose solutions.

Increased Automation

Automation is another area of potential growth in skiving technology. Automated skiving machines can streamline the process, reducing manual intervention and increasing overall efficiency. Automation may also improve consistency and accuracy, leading to higher-quality hydraulic hose assemblies.

The skiving revolution represents a significant advancement in hydraulic hose technology, offering numerous benefits that enhance performance, durability, and overall efficiency. By understanding and adopting skiving techniques, businesses, and operators can achieve more reliable and cost-effective hydraulic solutions. As technology continues to evolve, skiving will remain a critical component of hydraulic hose assembly, driving innovation and improving the performance of hydraulic systems across various industries.

Embracing the advantages of skiving technology not only enhances the reliability of hydraulic systems but also contributes to greater operational efficiency and reduced maintenance costs. As we look to the future, ongoing advancements in skiving technology will likely offer even more benefits, further revolutionizing the way we approach hydraulic hose solutions.

FAQs

What are the key benefits of skiving hydraulic hoses?

The key benefits include enhanced bond strength, improved pressure handling, increased durability, better flexibility, and reduced risk of hose slippage.

How does skiving improve the performance of hydraulic hoses?

Skiving improves performance by creating a stronger, more secure connection between the hose and its fittings, which enhances pressure handling and durability.

In which industries is skiving technology commonly used?

Skiving technology is widely used in industries such as construction, agriculture, manufacturing, and mining.

What are the future trends in skiving technology?

Future trends include advancements in skiving machinery, enhanced materials, and increased automation to improve precision and efficiency.

How does skiving compare to other hydraulic hose preparation methods?

Skiving offers superior bond strength and pressure handling compared to traditional methods, making it a preferred choice for high-performance hydraulic applications.